Are you curious about filter cartridge winding machines and their adaptability in various industries? In this guide, I will provide you with an overview of the filter cartridge winding machine, its features, and its applications.

The Functionality of Filter Cartridge Winding Machines

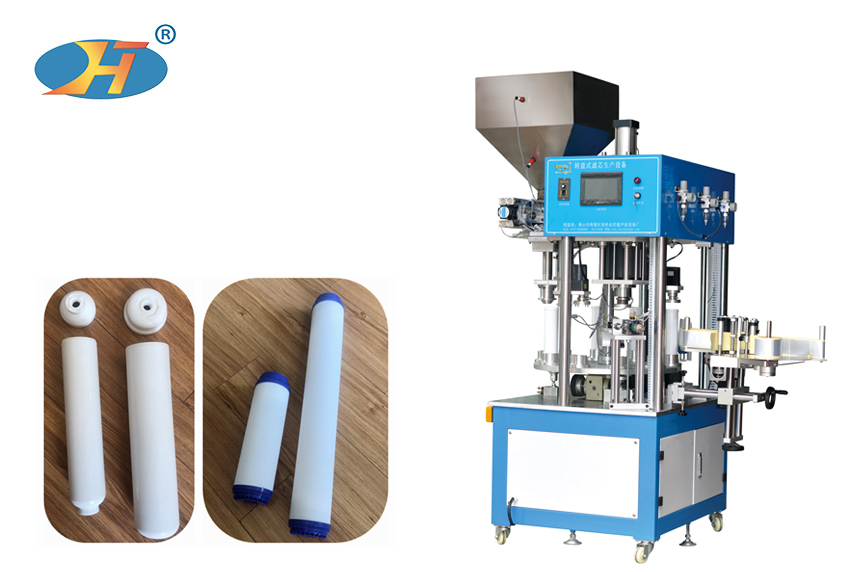

A filter cartridge winding machine is a specialized equipment used for manufacturing high-quality filter cartridges. It is designed to wind different types of filtration media onto a core or mandrel to create a sturdy and efficient filtering element.

This machine operates by precisely controlling the tension and speed at which the filtration media is wound onto the core. This ensures uniformity in pleat spacing, resulting in optimal filtration performance.

With advanced technology and automation capabilities, modern filter cartridge winding machines offer increased efficiency, accuracy, and productivity compared to traditional manual methods.

Hongteng: Leading Manufacturer of Filter Cartridge Winding Machines

Hongteng is a renowned manufacturer that specializes in producing top-notch filter cartridge winding machines. With years of experience in the industry, they have gained recognition for their innovative designs and reliable machinery.

Hongteng’s filter cartridge winding machines are known for their adaptability across various sectors such as water treatment plants, pharmaceuticals, food processing industries, chemical manufacturing units, and more. These machines can efficiently produce different types of filters tailored to meet specific requirements.

The Versatility of PP Spun Filter Manufacturing Machines

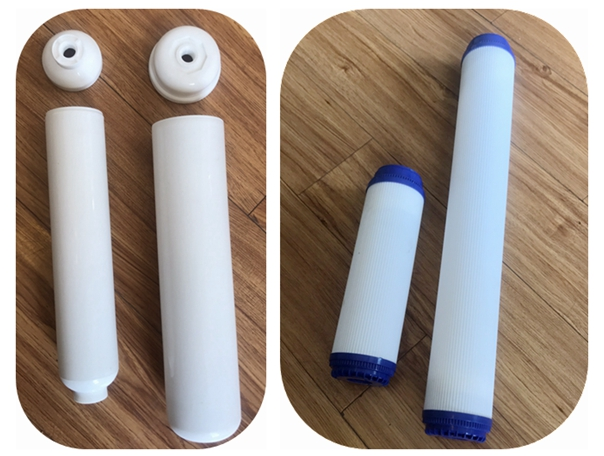

In addition to providing excellent quality filter cartridge winding machines,Hongteng also offers pp spun filter manufacturing machines. These versatile devices enable manufacturers to produce polypropylene (PP) spun filters widely used for liquid filtration purposes.

The PP spun filter manufacturing machine allows precise control over the winding process, ensuring consistent pleat spacing and accurate filter dimensions. This results in filters with enhanced filtration efficiency and longer service life.

These machines are highly adaptable to different production requirements, allowing manufacturers to produce a wide range of PP spun filters with varying diameters, lengths, micron ratings, and end cap configurations.

Conclusion

In conclusion, filter cartridge winding machines play a crucial role in the manufacturing of high-quality filter cartridges. Hongteng stands out as a leading manufacturer in this field by offering reliable and adaptable machinery for various industries.

Their expertise extends beyond filter cartridge winding machines to include PP spun filter manufacturing machines that enable efficient production of top-notch polypropylene spun filters. With their advanced technology and commitment to quality, Hongteng continues to meet the diverse needs of the filtration industry.